SERVICES

Manufacture

Our SERVICES

01

Manufacture

Makner provides a wide range of customer-centric services tailored to meet specific requirements in the following subjects.

Machining

This involves using various tools and machines to shape and fabricate components from raw materials, ensuring precision and accuracy in manufacturing.

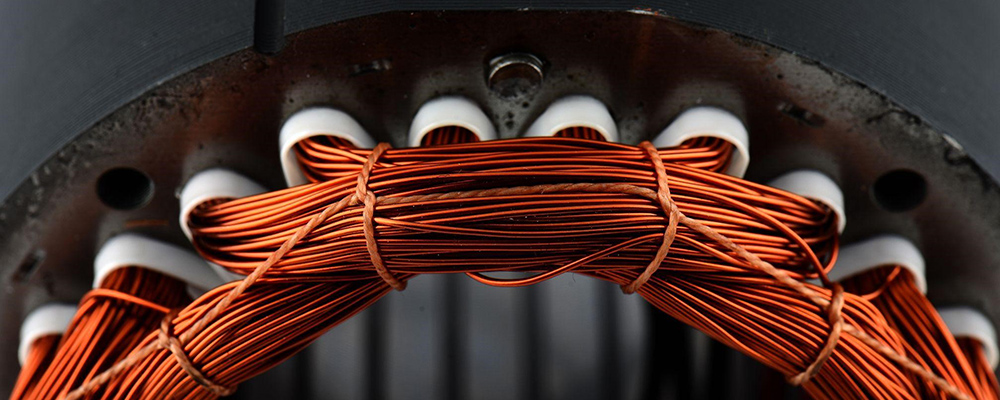

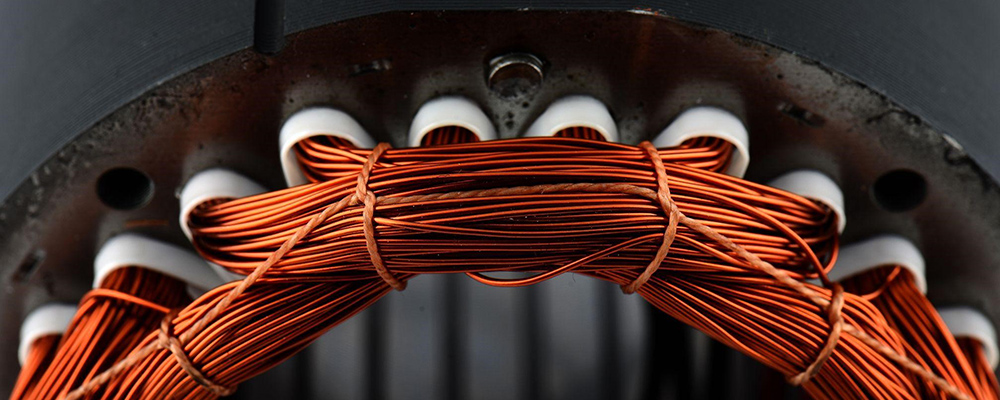

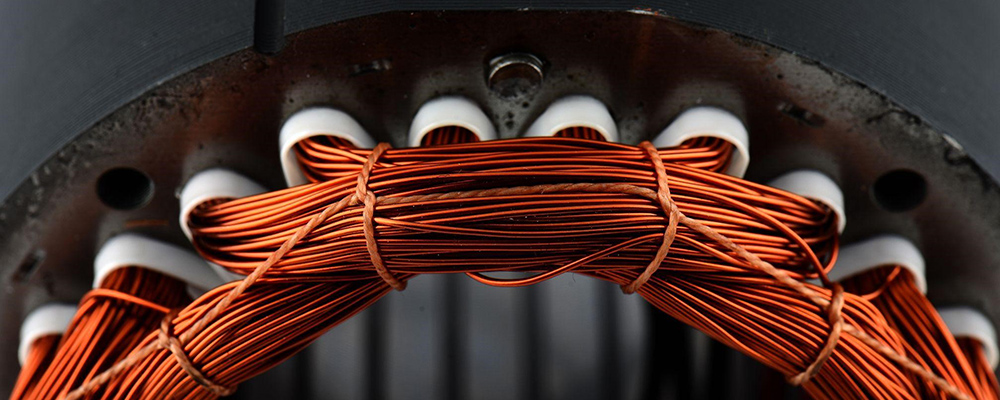

Winding

This process involves winding coils or conductive wire around a core to create electromagnetic components, such as motors, transformers, and inductors.

Sheet Metal Cutting and Lamination

Sheet metal cutting involves shaping metal sheets into specific forms or sizes, while lamination refers to assembling layers of materials to create composite structures, often used in the construction of motor cores.

Coating

In this context, coating likely refers to the protective coating or housing applied to the finished products to enhance durability and protection.

Electrostatic Powder Painting

This method is used for applying a durable and high-quality finish to the products, providing resistance to corrosion, chemicals, and wear.

Grinding

Grinding is a machining process that involves removing material from the surface of a workpiece using abrasive wheels or belts.

Magnet Supply

This likely refers to the provision of magnets used in electric motors or other magnetic applications.

Composite Part Production

This involves manufacturing components or parts using composite materials, which are known for their lightweight and high-strength properties.